Issue No. 251〔Delivered Products & Systems〕

Report on Delivery and Operational Condition of Largescale Grate-type (Stoker-type) Incinerator

in Nanchang City, Jiangxi, China

Author

Koji KOBAYASHI*

Kazushige KUROSAWA*

Motoshi ARIHARA*

Wenjie YANG**

Zhibao ZHANG**

Binglai ZHAO**

- *

Ebara Environmental Plant Co., Ltd.

- **

Ebara Qingdao Co., Ltd.

Keywords: China, Waste, Incinerator, Stoker, Calorific value, Combustion, Environmental, HPCC, Qingdao, Nanchang

1. Introduction

The plant was constructed by Nanchang Biomax Green Energy Limited a special purpose company (SPC) established by Beijing Capital Group Co., Ltd. which undertook the project from Nanchang government.The scope of Ebara’s contribution to the projects includes the basic design of the incineration system and supply of main equipment of the incinerators, auxiliary equipment, an automatic combustion control system (ACC), and other instruments (Figure 1).

Fig. 1 Nanchang Waste-to-Energy Plant

2. Overview of Nanchang

Nanchang City, the capital of Jiangxi Province, China, is the center of politics, economy and culture as well as strategic point of Jiangxi traffic. Poyang Lake, the largest freshwater lake in China, located in the northeast of the city. The city has an area of 7 402 km2 with a population of approximately 5.2 million. Nanchang has a monsoon-influenced humid subtropical climate with the annual average temperature of 16.8 °C. It is rainy season from April to June and approximately 80% of the annual precipitation falls during this period.

Nanchang is well known as a historical and cultural city built about 2200 years ago during the Han dynasty, and it is the largest industrial city in Jiangxi Province now.

Figure 2 shows the location of Nanchang in China.

Fig. 2 Location of Nanchang, Jiangxi, in China

3. Overview and characteristics of the plant

Table 1 shows the lower calorific values and composition of the waste in Nanchang.

| Item | Low-calorific value waste | Design waste | High-calorific value waste |

| Lower calorific value | 4180 kJ/kg | 6270 kJ/kg | 8360 kJ/kg |

| Moisture content | 58.81% | 52.01% | 45.21% |

| Combustible content | 26.41% | 33.56% | 40.71% |

| Ash content | 14.78% | 14.43% | 14.08% |

| (1) Incinerator | |

Type: | EBARA HPCC (High-Pressure Combustion Control) grate-type incinerator |

| Capacity: | 1200 t/d (600 t/24 h×2 units) |

| (2) Boiler | |

| Type: | Natural-circulation water tube boiler with superheaters |

| Capacity: | 53.2 t/h (Max. 58.5 t/h)×2 units |

| Steam condition: | 400 °C×4.0 MPaG (at the exit of the superheater) |

| (3) Steam turbine generator | |

| Type: | Steam turbine (condensing type)+generator |

| Rated power: | 12 MW×2 units |

| (4) Flue-gas treatment facility | |

| Flue-gas treatment system: | |

Semi-dry type system (slaked-lime slurry spraying) +dry type system (slaked-lime injection)+activated carbon injection+bag filter | |

| (5) Stack | |

| Type: | External wall - Reinforced concrete structure Internal cylinder - Steel |

| Height: | 80 m |

| (6) Emission values [flue gas from stack] | |

Inside [ ] are the values converted to the standard oxygen concentration used in Japan*1. | |

| Dust: | Less than 80 mg/m3 (NTP) (O2 11% equiv.)

[Less than 72 mg/m3 (NTP) (O2 12% equiv.)] |

| Sulfuroxide: | Less than 260 mg/m3 (NTP) (O2 11% equiv.)

[Less than 81.9 ppm (O2 12% equiv.)] |

| Nitrogen oxide: | Less than 400 mg/m3 (NTP) (O2 11% equiv.)

[Less than 175.4 ppm (O2 12% equiv.)] |

| Hydrogenchloride: | Less than 75 mg/m3 (NTP) (O2 11% equiv.)

[Less than 41.4 ppm (O2 12% equiv.)] |

| Carbonmonoxide: | Less than 150 mg/m3 (NTP) (O2 11% equiv.)

[Less than 108 ppm (O2 12% equiv.)] |

| Dioxins: | Less than 0.1 ng-TEQ/m3 (O2 11% equiv.)

[Less than 0.09 ng-TEQ/m3 (O2 12% equiv.)] |

Ash from the incineration furnace is cooled in the bottom ash discharger and transferred by vibrating conveyor to the ash bunker for temporary storage. Then, the ash is loaded onto an ash truck by ash crane and transported to outside of the plant.

Fly ash collected through the bag filter is fed by a conveyor to an ash silo for temporary storage. Then, it is kneaded in a fly ash treatment system and carried out on truck to a landfill site.

Fig. 3 Flow sheet of plant

4. Overview of the project

4.1 Scope of supply and performance warranty

In China, different from Japan, construction of Waste to Energy Plants is often is undertaken by the SPC itself which secures the project. Consequently, we are responsible for the basic design (including a part of detailed design) of the incineration system, delivering main equipment (grates, hydraulic drive unit, burners, ACC system, and waste hopper level sensor), and dispatching supervisors.

The following is guaranteed items and values:

| (1) Annual total operation hours | :8 000 hours or longer |

| (2) Operating load (incineration amount) range | :60 to 110% |

| (Within 2 hours/day for 110% load) | |

| (3) Furnace outlet temperature | :850 °C or higher, for 2 seconds or longer |

| (4) Ash ignition loss | : 3% or less |

| (5) Boiler efficiency | :80% or higher |

| (6) Grate replacement ratio | :Less than 1% for 8 000 hours in operation

Less than 2% for 16 000 hours in operation Less than 2.5% for 24 000 hours in operation Less than 3% for 32 000 hours in operation |

4.2 Construction schedule

Fig. 4 Grate installation

Fig. 5 Waste feeder installation

5. Characteristics of the plant

5.1 Adoption of 4-row grate incinerator

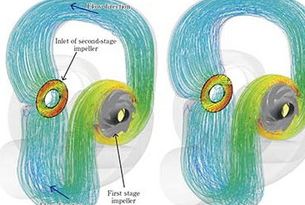

We have been delivered a lot of furnaces which adopt 3-run structure in China as well as in Japan. 4-run structure was firstly employed for Nanchang Plant. Figure 6 shows the structure of the 4-row grate incinerator.

The basic structure of each row is the same as the incinerators previously delivered in China; along the traveling direction of waste, the grate is divided into the following parts: a drying grate, combustion grates I and II, and post-combustion grate. Each grate can be independently driven, and the number of movements per unit time to be set individually.

To address the low-calorific-value waste in China, we increased the length of the entire grate compared with that for the plants in Japan, and provided steps at the exit of the drying grate and the entrance of the post-combustion grate to loosen waste and facilitate incinerating it.

Combustion air is supplied through the under-furnace chutes located at the bottom of the grate and the quantity of airflow is adjustable on a chute-by-chute basis. By adjusting the number of movements of each grate and the quantity of combustion air for each chute according to the nature and amount of waste, it is possible to realize stable combustion handling a variety of waste types.

The 4-row-grate incinerator is composed of 4 rows of units arranged along the width direction, and width dimension is wider than the prior incinerators. Therefore we strengthened the structure of each section to prevent from bending.

In addition, a large, wide grate-type incinerator may cause inhomogeneous combustion in the width direction within the furnace. To prevent this, we installed in the width direction several cameras for monitoring the inside of the furnace to enable the combustion air to be adjusted on a row-by-row basis according to the combustion conditions in each rows.

Also the incinerators for this plant has high capacity to overload operation, and achieved an average treatment rate of 670 t/d (112% load) and a maximum treatment rate of 733 t/d (122% load) against the rated treatment rate of 600 t/d (in China, overload operation is not legally restricted and therefore continuous overload operation is allowed provided that equipment safety is ensured).

As a result, we successfully verified the effectiveness of the approach of upscaling by combining multiple units in the width direction, revealing that the same approach can be used for further upscaling.c

Figure 7 shows the actual combustion state inside of the incineration furnaces.

Fig. 6 Structure of the 4-row grate incinerator

Fig. 7 Situation of combustion

5.2 Upsizing of bottom ash discharger

Fig. 8 Bottom ash discharger installation

5.3 Adoption of a grate-bearing cooling structure

| Position | Combustion grateⅠ | Combustion grateⅡ |

| WEIHAI without bearing cooling | 162 | 152 |

| NANCHANG with bearing cooling | 111 | 109.5 |

| Temperature difference | 51 | 42.5 |

5.4 Flue-gas recirculation for NOx reduction1)

Fig. 9 Trend of NOx with flue gas recirculation

6. Operation condition and performance test results

6.1 Operating condition

Fig. 10 Trend of furnace outlet temperature and steam generation

6.2 Performance test results

Table 4 shows the performance test results.

| Test item | Unit | Guaranteed performance | No.1 furnace | No.2 furnace | Conclusion |

| Volume of waste treatment | t/d | 600.0 | 665 | 605 | Qualified |

| Boiler total efficiency | % | ≧80.00 | 80.25 | 82.6 | Qualified |

| Steam flow | t/h | 53.2 | 54 | 54.13 | Qualified |

| Steam temperature | ℃ | 400 (+10,−5) | 400 | 398.9 | Qualified |

| Steam pressure | MPa | 4.00 (+0.2,−0.3) | 3.92 | 3.95 | Qualified |

| Ash ignition loss | % | ≦3.00 | 1.72 | 1.14 | Qualified |

| Retention time of flue gas of 850 °C or higher | s | ≧2.0 | 4.8 | 5.3 | Qualified |

| Lower calorific value of waste | kJ/kg | 6270.0 | 6132 | 6605 | −※ |

※ Excluded from the qualification judgment because the performance of this test item is not guaranteed.

6.3 110% load operation

Figure 11 shows the actually treated waste amount during the one-month period of the load test run.

Fig. 11 The waste incineration load for one month

7. Conclusion

In recent years, environmental awareness has been raised in China as well, upgrading the technology required for Waste-to-Energy plants. We are committed to responding to requests from the Chinese market by achieving technological improvements based on our experience.

We has been consistently receiving orders for incinerators from the Chinese market. Another several plants based on our incinerators are to be completed in China. So far, we have published in the Ebara Engineering Review the cases2), 3) in which we delivered large grate-type incinerators to plants in China, including this one. We will continue to report such cases in this journal.

Finally, we should like to express our grateful thanks to all the people who cooperated to this project.

References

Recommended articles

Inquiry about Ebara Engineering Review